Page 13 - Turning_catalog_INCH_2022_45_P113-260

P. 13

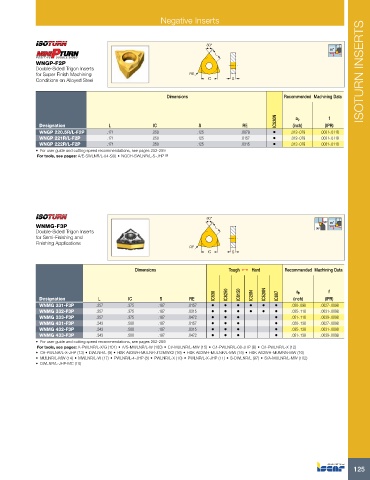

Negative Inserts

80°

L 95 º

WNGP-F2P

Double-Sided Trigon Inserts

for Super Finish Machining RE ISOTURN INSERTS

Conditions on Alloyed Steel IC S

Dimensions Recommended Machining Data

IC530N ap f

Designation L IC S RE (inch) (IPR)

WNGP 220.5R/L-F2P .171 .250 .125 .0079 • .012-.079 .0031-.0118

WNGP 221R/L-F2P .171 .250 .125 .0157 • .012-.079 .0031-.0118

WNGP 222R/L-F2P .171 .250 .125 .0315 • .012-.079 .0031-.0118

• For user guide and cutting speed recommendations, see pages 252-259

For tools, see pages: A/E-SWLNR/L-04 (99) • NQCH-SWLNR/L-S-JHP (8)

80°

WNMG-F3P L 95° 95° 95 º

Double-Sided Trigon Inserts

for Semi-Finishing and

Finishing Applications

RE

IC S

Dimensions Tough 1 Hard Recommended Machining Data

IC830 IC8250 IC8150 IC20N IC520N IC807 ap f

Designation L IC S RE (inch) (IPR)

WNMG 331-F3P .257 .375 .187 .0157 • • • • • • .020-.098 .0027-.0098

WNMG 332-F3P .257 .375 .187 .0315 • • • • • • .035-.118 .0031-.0098

WNMG 333-F3P .257 .375 .187 .0472 • • • • .051-.118 .0039-.0098

WNMG 431-F3P .343 .500 .187 .0157 • • • • .020-.138 .0027-.0098

WNMG 432-F3P .343 .500 .187 .0315 • • • • .035-.138 .0031-.0098

WNMG 433-F3P .343 .500 .187 .0472 • • • • .051-.138 .0039-.0098

• For user guide and cutting speed recommendations, see pages 252-259

For tools, see pages: A-PWLNR/L-X/G (101) • A/S-MWLNR/L-W (100) • C#-MULNR/L-MW (15) • C#-PWLNR/L-08-JHP (9) • C#-PWLNR/L-X (12)

• C#-PWLNR/L-X-JHP (13) • DWLNR/L (9) • HSK A63WH-MULNR-J12MWX2 (16) • HSK A63WH-MULNR/L-MW (15) • HSK A63WH-MUMNN-MW (16)

• MULNR/L-MW (14) • MWLNR/L-W (17) • PWLNR/L-4-JHP (8) • PWLNR/L-X (10) • PWLNR/L-X-JHP (11) • S-DWLNR/L (97) • S/A-MULNR/L-MW (102)

• DWLNR/L-JHP-MC (10)

125