Page 8 - HOLE_MAKING_CATALOG_INCH_2022_P187-P236

P. 8

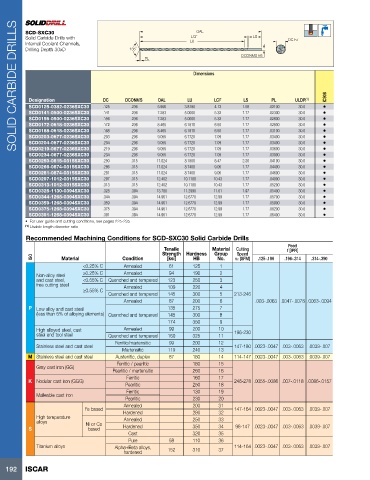

SOLID CARBIDE DRILLS

SCD-SXC30 OAL

Solid Carbide Drills with LCF LS DC h7

Internal Coolant Channels, LU

Drilling Depth 30xD 135

DCONMS h6

PL

Dimensions

IC908

Designation DC DCONMS OAL LU LCF LS PL ULDR (1)

SCD0125-0382-0236SXC30 .125 .236 5.906 3.8190 4.13 1.58 .02100 30.0 •

SCD0141-0500-0236SXC30 .141 .236 7.283 5.0000 5.32 1.77 .02300 30.0 •

SCD0156-0500-0236SXC30 .156 .236 7.283 5.0000 5.32 1.77 .02600 30.0 •

SCD0172-0618-0236SXC30 .172 .236 8.465 6.1810 6.50 1.77 .02800 30.0 •

SCD0188-0618-0236SXC30 .188 .236 8.465 6.1810 6.50 1.77 .03100 30.0 •

SCD0203-0677-0236SXC30 .203 .236 9.055 6.7720 7.09 1.77 .03400 30.0 •

SCD0204-0677-0236SXC30 .204 .236 9.055 6.7720 7.09 1.77 .03400 30.0 •

SCD0219-0677-0236SXC30 .219 .236 9.055 6.7720 7.09 1.77 .03600 30.0 •

SCD0234-0677-0236SXC30 .234 .236 9.055 6.7720 7.09 1.77 .03900 30.0 •

SCD0250-0815-0315SXC30 .250 .315 11.024 8.1500 8.47 2.36 .04100 30.0 •

SCD0266-0874-0315SXC30 .266 .315 11.024 8.7400 9.06 1.77 .04400 30.0 •

SCD0281-0874-0315SXC30 .281 .315 11.024 8.7400 9.06 1.77 .04600 30.0 •

SCD0297-1012-0315SXC30 .297 .315 12.402 10.1180 10.43 1.77 .04900 30.0 •

SCD0313-1012-0315SXC30 .313 .315 12.402 10.1180 10.43 1.77 .05200 30.0 •

SCD0328-1130-0394SXC30 .328 .394 13.780 11.2990 11.61 1.97 .05400 30.0 •

SCD0344-1268-0394SXC30 .344 .394 14.961 12.6770 12.99 1.77 .05700 30.0 •

SCD0359-1268-0394SXC30 .359 .394 14.961 12.6770 12.99 1.77 .05900 30.0 •

SCD0375-1268-0394SXC30 .375 .394 14.961 12.6770 12.99 1.77 .06200 30.0 •

SCD0391-1268-0394SXC30 .391 .394 14.961 12.6770 12.99 1.77 .06400 30.0 •

• For user guide and cutting conditions, see pages 225-235

(1) Usable length diameter ratio

Recommended Machining Conditions for SCD-SXC30 Solid Carbide Drills

Feed

Tensile Material Cutting f [IPR]

Strength Hardness Group Speed

ISO Material Condition [ksi] HB No. vc [SFM] .125-.196 .196-.314 .314-.390

<0.25% C Annealed 61 125 1

Non-alloy steel ≥0.25% C Annealed 94 190 2

and cast steel, <0.55% C Quenched and tempered 123 250 3

free cutting steel Annealed 109 220 4

≥0.55% C

Quenched and tempered 145 300 5 213-246

Annealed 87 200 6 .003-.0063 .0047-.0078 .0063-.0094

P Low alloy and cast steel 135 275 7

(less than 5% of alloying elements) Quenched and tempered 145 300 8

174 350 9

High alloyed steel, cast Annealed 99 200 10 196-230

steel and tool steel Quenched and tempered 160 325 11

Ferritic/martensitic 99 200 12

Stainless steel and cast steel 147-180 .0023-.0047 .003-.0063 .0039-.007

Martensitic 119 240 13

M Stainless steel and cast steel Austenitic, duplex 87 180 14 114-147 .0023-.0047 .003-.0063 .0039-.007

Ferritic / pearlitic 180 15

Gray cast iron (GG)

Pearlitic / martensitic 260 16

Ferritic 160 17

K Nodular cast iron (GGG) 246-278 .0055-.0086 .007-.0118 .0086-.0157

Pearlitic 250 18

Ferritic 130 19

Malleable cast iron

Pearlitic 230 20

Annealed 200 31

Fe based Hardened 280 32 147-164 .0023-.0047 .003-.0063 .0039-.007

High temperature Annealed 250 33

alloys Ni or Co

S based Hardened 350 34 98-147 .0023-.0047 .003-.0063 .0039-.007

Cast 320 35

Pure 58 110 36

Titanium alloys Alpha+Beta alloys, 114-164 .0023-.0047 .003-.0063 .0039-.007

hardened 152 310 37

192 ISCAR