Page 4 - Turning_catalog_INCH_2022_45_P509-690

P. 4

PARTING PARTING SELECTION GUIDE

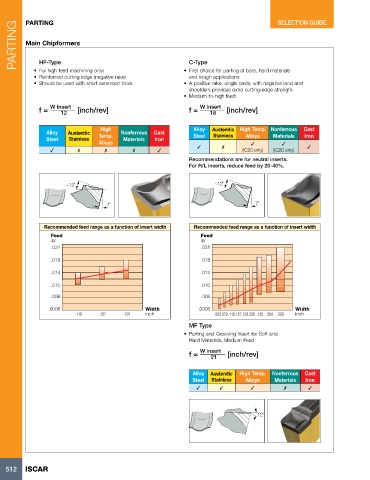

Main Chipformers

HF-Type

C-Type

• For high feed machining only!

and tough applications

• Reinforced cutting edge (negative rake) • First choice for parting of bars, hard materials

• Should be used with short extension tools • A positive rake, single cavity with negative land and

shoulders provides extra cutting-edge strength

• Medium-to-high feed

f ≈ W insert [inch/rev] f ≈ W insert [inch/rev]

18

12

High Alloy Austenitic High Temp. Nonferrous Cast

Alloy Austenitic Nonferrous Cast Stainless

Steel Stainless Temp. Materials Iron Steel Alloys Materials Iron

Alloys 3 3

3 7 3

3 7 7 7 3 (IC20 only) (IC20 only)

Recommendations are for neutral inserts.

For R/L inserts, reduce feed by 20-40%.

~12˚ ~12˚

7˚ 7˚

Recommended feed range as a function of insert width Recommended feed range as a function of insert width

Feed Feed

ipr ipr

.031 .031

.018 .018

.014 .014

.010 .010

.006 .006

.0008 Width .0008 Width

.118 .157 .197 inch .063.079 .118.157 .139.236 .315 .354 .500 inch

MF Type

• Parting and Grooving Insert for Soft and

Hard Materials, Medium Feed

f ≈ W insert [inch/rev]

21

Alloy Austenitic High Temp. Nonferrous Cast

Steel Stainless Alloys Materials Iron

3 3 3 7 3

12°

512 ISCAR