Page 16 - ECO SOLID LINE

P. 16

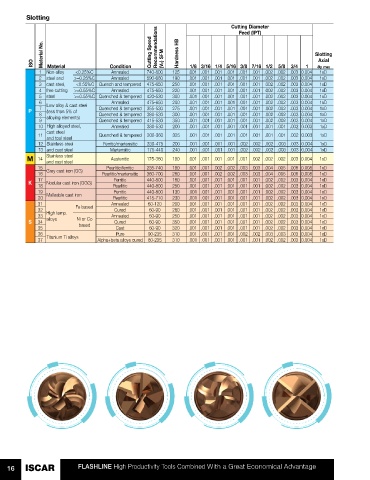

Slotting Cutting Diameter

Feed (IPT)

Material No. Cutting Speed Recommendations Hardness HB Slotting

Axial

ISO Material Condition (Vc) SFM 1/8 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4 1 ap max

1 Non-alloy <0.25%C Annealed 740-800 125 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

2 steel and >=0.25%C Annealed 590-680 190 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

3 cast steel, <0.55%C Quench and tempered 475-650 250 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

4 free cutting >=0.55%C Annealed 475-650 220 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

5 steel >=0.55%C Quenched & tempered 420-530 300 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

6 Low alloy & cast steel Annealed 475-650 200 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

P 7 (less than 5% of Quenched & tempered 355-530 275 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

8 alloying elements) Quenched & tempered 380-530 300 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

9 Quenched & tempered 415-530 350 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

10 High alloyed steel, Annealed 380-530 200 .001 .001 .001 .001 .001 .001 .001 .001 .002 0.003 1xD

cast steel

11 Quenched & tempered 200-360 325 .001 .001 .001 .001 .001 .001 .001 .001 .002 0.003 1xD

and tool steel

12 Stainless steel Ferritic/martensitic 230-475 200 .001 .001 .001 .001 .002 .002 .002 .003 .003 0.004 1xD

13 and cast steel Martensitic 175-440 240 .001 .001 .001 .001 .002 .002 .002 .003 .003 0.004 1xD

Stainless steel

M 14 and cast steel Austenitic 175-360 180 .001 .001 .001 .001 .001 .002 .002 .002 .003 0.004 1xD

15 Grey cast iron (GG) Pearlitic/ferritic 235-740 180 .001 .001 .002 .002 .003 .003 .004 .005 .006 0.008 1xD

16 Pearlitic/martensitic 380-700 260 .001 .001 .002 .002 .003 .003 .004 .005 .006 0.008 1xD

K 17 Nodular cast iron (GGG) Ferritic 440-800 160 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

18 Pearlitic 440-800 250 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

19 Malleable cast iron Ferritic 440-800 130 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

20 Pearlitic 415-710 230 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

31 Fe based Annealed 60-120 200 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

32 High temp. Cured 60-90 280 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

33 Annealed 60-90 250 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

S 34 alloys Ni or Co Cured 60-90 350 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

based

35 Cast 60-90 320 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

36 Titanium Ti alloys Pure 90-235 310 .001 .001 .001 .001 .002 .002 .003 .003 .003 0.004 1xD

37 Alpha+beta alloys cured 80-235 310 .001 .001 .001 .001 .001 .001 .002 .002 .003 0.004 1xD

Roughing

Cutting Diameter Profiling Radial

Feed (IPT)

Material No. Cutting Speed Recommendations Hardness HB

ISO Material Condition Vc (sfm) 1/8 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4 1 ap ae

.75xD-

1 <0.25%C Annealed 985-1000 125 .001 .001 .001 .001 .002 .002 .003 .003 .004 .005 .25xD-.4xD

1.5xD

.75xD-

2 Non-alloy >=0.25%C Annealed 785-850 190 .001 .001 .001 .001 .002 .002 .003 .003 .004 .005 1.5xD .25xD-.4xD

steel and cast Quench and .75xD-

3 <0.55%C 630-810 250 .001 .001 .001 .001 .002 .002 .003 .003 .004 .005 .25xD-.4xD

steel, free tempered 1.5xD

4 cutting steel >=0.55%C Annealed 630-810 220 .001 .001 .001 .001 .002 .002 .003 .003 .004 .005 .75xD- .25xD-.4xD

1.5xD

Quenched & .75xD-

5 >=0.55%C 560-660 300 .001 .001 .001 .001 .002 .002 .003 .003 .004 .005 .25xD-.4xD

tempered 1.5xD

.75xD-

6 Annealed 630-810 200 .001 .001 .001 .001 .002 .002 .003 .003 .004 .005 1.5xD .25xD-.4xD

Quenched & .75xD-

P 7 Low alloy & cast steel tempered 470-660 275 .0006 .001 .001 .001 .002 .002 .002 .003 .004 .005 1.5xD .25xD-.4xD

(less than 5% of Quenched & .75xD-

8 alloying elements) 500-660 300 .0006 .001 .001 .001 .002 .002 .002 .003 .004 .005 .25xD-.4xD

tempered 1.5xD

Quenched & .75xD-

9 550-660 350 .0006 .001 .001 .001 .002 .002 .002 .003 .004 .005 .25xD-.4xD

tempered 1.5xD

.75xD-

10 High alloyed steel, Annealed 500-660 200 .0004 .0007 .001 .001 .001 .001 .002 .002 .003 .003 1.5xD .25xD-.4xD

cast steel and tool steel Quenched & .75xD-

11 270-450 325 .0004 .0007 .001 .001 .001 .001 .002 .002 .003 .003 .25xD-.4xD

tempered 1.5xD

Ferritic/ .75xD-

12 310-590 200 .0007 .001 .001 .002 .002 .002 .003 .004 .004 .006 .25xD-.4xD

Stainless steel and cast steel martensitic 1.5xD

13 Martensitic 235-550 240 .0007 .001 .001 .002 .002 .002 .003 .004 .004 .006 .75xD- .25xD-.4xD

1.5xD

16 ISCAR FLASHLINE High Productivity Tools Combined With a Great Economical Advantage

.75xD-

M 14 Stainless steel and cast steel Austenitic 235-450 180 .0005 .0007 .001 .001 .001 .002 .002 .002 .003 .004 .25xD-.4xD

1.5xD

.75xD-

15 Pearlitic/ferritic 310-925 180 .001 .001 .001 .002 .003 .003 .004 .005 .006 .008 .25xD-.4xD

1.5xD

Grey cast iron (GG) Pearlitic/ .75xD-

16 500-875 260 .001 .001 .001 .002 .003 .003 .004 .003 .006 .008 .25xD-.4xD

martensitic 1.5xD

.75xD-

17 Ferritic 590-1000 160 .0006 .001 .001 .002 .003 .002 .002 .003 .004 .005 .25xD-.4xD

1.5xD

K Nodular cast iron (GGG) .75xD-

18 Pearlitic 590-1000 250 .0006 .001 .001 .001 .002 .002 .002 .003 .004 .005 .25xD-.4xD

1.5xD

.75xD-

19 Ferritic 590-1000 130 .0006 .001 .001 .001 .002 .002 .002 .003 .004 .005 .25xD-.4xD

Malleable cast iron 1.5xD

20 Pearlitic 550-890 230 .0006 .001 .001 .001 .002 .002 .002 .003 .004 .005 .75xD- .25xD-.4xD

1.5xD

.75xD-

31 Annealed 80-150 200 .0007 .001 .001 .001 .002 .002 .003 .003 .004 .005 .25xD-.4xD

Fe based 1.5xD

32 Cured 80-115 280 .0007 .001 .001 .001 .002 .002 .003 .003 .004 .005 .75xD- .25xD-.4xD

1.5xD

High temp. .75xD-

33 Annealed 80-115 250 .0007 .001 .001 .001 .002 .002 .003 .003 .004 .005 .25xD-.4xD

alloys 1.5xD

Ni or Co .75xD-

S 34 Cured 80-115 350 .0007 .001 .001 .001 .002 .002 .003 .003 .004 .005 .25xD-.4xD

based 1.5xD

.75xD-

35 Cast 80-115 320 .0007 .001 .001 .001 .002 .002 .003 .003 .004 .005 .25xD-.4xD

1.5xD

.75xD-

36 Pure 120-295 310 .0006 .001 .001 .001 .002 .002 .002 .002 .003 .004 .25xD-.4xD

1.5xD

Titanium Ti alloys Alpha+beta .75xD-

37 110-220 310 .0006 .001 .001 .001 .002 .002 .002 .002 .003 .004 .25xD-.4xD

alloys cured 1.5xD

55 .75xD-

38 Hardened 110-210 0.001 0.001 0.001 0.001 0.002 0.002 0.003 0.003 0.004 0.005 .02xD

1.5xD

Hardened Steel HRC .75xD-

60

39 Hardened 110-145 0.001 0.001 0.001 0.001 0.002 0.002 0.003 0.003 0.004 0.005 .02xD

1.5xD

H HRC .75xD-

40 Chilled Cast Iron Cast 250-320 400 0.001 0.001 0.001 0.001 0.002 0.002 0.003 0.003 0.004 0.005 .02xD

1.5xD

55 .75xD-

41 Cast Iron Hardened 110-210 0.001 0.001 0.001 0.001 0.002 0.002 0.003 0.003 0.004 0.005 .02xD

HRC 1.5xD

Semi-Finish Cutting Diameter Profiling

Radial

Feed (IPT)

Material No. Cutting Speed Recommendations Hardness HB

ISO Material Condition Vc (sfm) 1/8 3/16 1/4 5/16 3/8 7/16 1/2 5/8 3/4 1 ap ae

1 <0.25%C Annealed 1230 125 .0005 .0008 .001 .001 .001 .001 .002 .002 .002 .003 1xD .05xD

2 Non-alloy >=0.25%C Annealed 1015 190 .0005 .0008 .001 .001 .001 .001 .002 .002 .002 .003 1xD .05xD

3 steel and cast <0.55%C Quench and 900 250 .0005 .0008 .001 .001 .001 .001 .002 .002 .002 .003 1xD .05xD

steel, free tempered

4 cutting steel >=0.55%C Annealed 900 220 .0005 .0008 .001 .001 .001 .001 .002 .002 .002 .003 1xD .05xD

5 >=0.55%C Quenched 760 300 .0005 .0008 .001 .001 .001 .001 .002 .002 .002 .003 1xD .05xD

& tempered

6 Annealed 900 200 .0005 .0008 .001 .001 .001 .001 .002 .002 .002 .003 1xD .05xD

Quenched

7 Low alloy & cast steel 710 275 .0005 .0007 .001 .001 .001 .001 .002 .002 .003 .004 1xD .05xD

P (less than 5% of & tempered

8 Quenched 730 300 .0005 .0007 .001 .001 .001 .001 .002 .002 .003 .004 1xD .05xD

alloying elements) & tempered

Quenched

9 760 350 .0005 .0007 .001 .001 .001 .001 .002 .002 .003 .004 1xD .05xD

& tempered

10 High alloyed steel, Annealed 730 200 .0003 .0004 .0005 .0006 .0008 .0009 .001 .001 .001 .002 1xD .05xD

11 cast steel and tool steel Quenched 450 325 .0003 .0004 .0005 .0006 .0008 .0009 .001 .001 .001 .002 1xD .05xD

& tempered

12 Ferritic/ 570 200 .0004 .0007 .001 .001 .001 .001 .002 .002 .003 .003 1xD .05xD

Stainless steel and cast steel martensitic

13 Martensitic 490 240 .0004 .0007 .001 .001 .001 .001 .002 .002 .003 .003 1xD .05xD

14 Stainless steel and cast steel Austenitic 425 180 .0004 .0005 .0007 .001 .001 .001 .001 .001 .002 .003 1xD .05xD

Pearlitic/

15 780 180 .001 .001 .002 .002 .003 .003 .003 .004 .005 .007 1xD .05xD

ferritic

Grey cast iron (GG) Pearlitic/

16 870 260 .001 .001 .002 .002 .003 .003 .003 .004 .005 .007 1xD .05xD

K 17 martensitic 990 160 .0004 .0006 .0008 .001 .001 .001 .001 .002 .002 .003 1xD .05xD

Ferritic

18 Nodular cast iron (GGG) Pearlitic 990 250 .0004 .0006 .0008 .001 .001 .001 .001 .002 .002 .003 1xD .05xD

19 Malleable cast iron Ferritic 990 130 .0004 .0006 .0008 .001 .001 .001 .001 .002 .002 .003 1xD .05xD

20 Pearlitic 900 230 .0004 .0006 .0008 .001 .001 .001 .001 .002 .002 .003 1xD .05xD

31 Fe based Annealed 145 200 .0003 .0004 0.006 .0007 .0008 .001 .001 .001 .002 .002 1xD .05xD

32 High temp. Cured 120 280 .0003 .0004 0.006 .0007 .0008 .001 .001 .001 .002 .002 1xD .05xD

33 alloys Annealed 120 250 .0003 .0004 0.006 .0007 .0008 .001 .001 .001 .002 .002 1xD .05xD

S 34 Ni or Co based Cured 120 350 .0003 .0004 0.006 .0007 .0008 .001 .001 .001 .002 .002 1xD .05xD

35 Cast 120 320 .0003 .0004 0.006 .0007 .0008 .001 .001 .001 .002 .002 1xD .05xD

36 Pure 260 310 .0003 .0004 0.006 .0007 .001 .001 .001 .001 .002 .002 1xD .05xD

Titanium Ti alloys Alpha+beta

37 alloys cured 250 310 .0003 .0004 0.006 .0007 .001 .001 .001 .001 .002 .002 1xD .05xD

38 Hardened Steel Hardened 110-210 55 HRC .0003 .0004 0.006 .0007 .0008 .001 .001 .001 .002 .002 1xD .02xD

39 Hardened 110-145 60 HRC .0003 .0004 0.006 .0007 .0008 .001 .001 .001 .002 .002 1xD .02xD

H 40 Chilled Cast Iron Cast 250-320 400 .0003 .0004 0.006 .0007 .0008 .001 .001 .001 .002 .002 1xD .02xD

41 Cast Iron Hardened 110-210 55 HRC .0003 .0004 0.006 .0007 .0008 .001 .001 .001 .002 .002 1xD .02xD